Key Methods to Prevent Machine Screws from Loosening

1. Use Thread Locker Adhesives

Applying thread locker glue (such as Loctite) to the screw threads before fastening is a widely used method. It increases friction between threads, preventing screws from backing out due to vibration or thermal expansion/contraction. Clean the screw threads thoroughly with a solvent before applying the thread locker, and apply only the recommended amount to avoid overuse. Different strengths (blue for removable, red for permanent) are available depending on whether the screw needs to be removed later.2. Employ Locking Nuts and Washers

- Nyloc nuts: These have a nylon insert that squeezes the threads to add friction and prevent loosening.

- Jam nuts: Two nuts tightened against each other lock in place to prevent loosening.

- Lock washers: Special washers with teeth or wedge shapes (e.g., Nord-Lock washers) increase friction and resist vibration-induced loosening. However, some types like split washers may not be effective under heavy vibration.

- Flanged nuts: Provide a larger bearing surface to reduce deformation and increase friction.

3. Mechanical Locking Devices

- Castle nuts with cotter pins or safety wire: Physically prevent rotation by locking the nut in place.

- Double nuts: Two nuts tightened against each other or with different thread pitches can prevent loosening by converting loosening force into tightening force.

- Distorted thread locking screws: Screws with intentional thread deformation to increase friction.

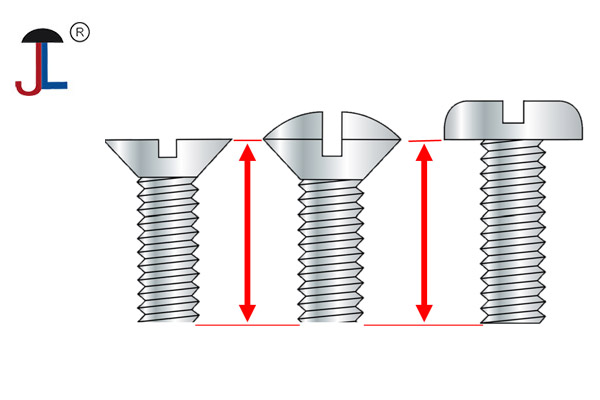

4. Use Correct Screws and Proper Installation

- Select screws with adequate length and diameter to ensure sufficient thread engagement. Short or thin screws are more prone to loosening.

- Use the correct type of screw for the material (e.g., countersunk screws for wood).

- Tighten screws to the proper torque specification to ensure adequate clamp force without over-tightening.

5. Additional Tips

- Use washers to distribute load and reduce vibration effects. Plastic washers can help in electronic or lightweight applications.

- In some cases, filling oversized screw holes with wood filler or a thread stopper product can help maintain grip.

- Avoid over-tightening as it can damage threads and reduce clamp force.

- For applications exposed to temperature changes or vibration, combining methods (e.g., thread locker plus lock washer) can improve reliability

Summary Table of Common Anti-Loosening Methods

| Method | Description | Best Use Case |

|---|---|---|

| Thread locker adhesive | Chemical bonding to increase friction | Metal-to-metal, removable or permanent |

| Nyloc nuts | Nylon insert adds friction | General mechanical fastening |

| Jam nuts | Two nuts tightened against each other | High vibration environments |

| Lock washers | Washers with teeth or wedges for friction | Moderate vibration, non-critical |

| Castle nuts + cotter pin | Mechanical locking with pin | Critical safety applications |

| Proper screw selection | Correct size/type and torque | All applications |

| Filling oversized holes | Use wood filler or thread stopper | Wood or plastic materials |

By combining these approaches-especially using thread locker adhesives, lock nuts or washers, and ensuring proper screw selection and torque-you can effectively prevent machine screws from loosening under vibration, thermal changes, or repeated use.