Rivets are simple, reliable fasteners whose load‐bearing capacity depends chiefly on three factors:

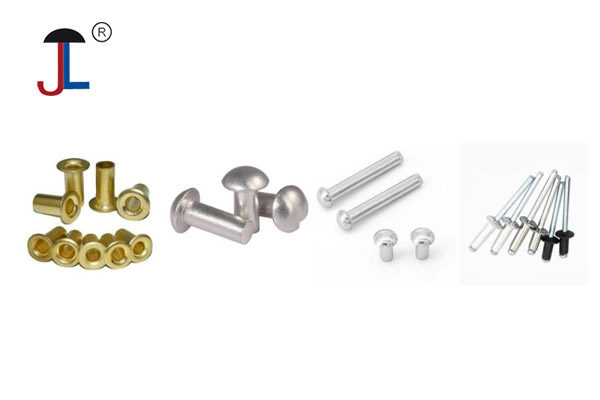

- Material (aluminum, steel, stainless steel, Monel, etc.)

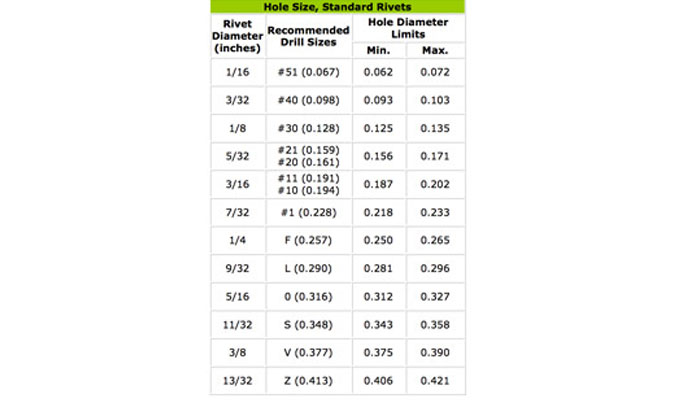

- Diameter of the rivet shank

- Type (solid vs. blind/pop rivet)

Below is a rough guide to the typical shear and tensile capacities of common solid rivets:

| Rivet Material | Diameter (in) | Shear Strength (lbf) | Tensile Strength (lbf) |

|---|---|---|---|

| 2024-T4 Aluminum | 1/8″ (3.2 mm) | ~1,200 lbf | ~1,600 lbf |

| 2024-T4 Aluminum | 3/16″ (4.8 mm) | ~2,700 lbf | ~3,200 lbf |

| Mild Steel (1020) | 1/8″ | ~3,000 lbf | ~4,200 lbf |

| Mild Steel (1020) | 3/16″ | ~6,700 lbf | ~9,300 lbf |

| 304 Stainless Steel | 1/8″ | ~3,500 lbf | ~5,000 lbf |

| Monel | 1/8″ | ~4,500 lbf | ~6,500 lbf |

Shear strength is the force required to slide the joined plates apart along the plane of the rivet.

Tensile strength is the force pulling the rivet straight out of the hole.

How to estimate rivet capacity

-

Calculate cross-sectional area of the shank:

-

Multiply by the material’s allowable stress.

- For aluminum rivets, a safe design shear stress is around 12–14 ksi (8.3–9.6 kg/mm²).

- For steel rivets, use about 30 ksi (21 kg/mm²).

Example for a 1/8″ (0.125 in) steel rivet in shear:

(Note: this theoretical value is lower than the empirical ~3,000 lbf because design stresses are conservative.)

Factors that reduce real‐world strength

- Hole quality: oversize or out-of-round holes reduce grip.

- Proximity to edges: rivets too close to sheet edges can tear out.

- Installation quality: insufficient bucking, improper stem pull, or high setting speed can induce cracks or incomplete forming.

- Fatigue loading: cyclic loads significantly lower allowable working stress.

Blind (pop) rivets vs. solid rivets

Blind rivets (e.g. aluminum body with steel mandrel) tend to have lower capacities. A typical 1/8″ aluminum pop rivet might only manage ~500 lbf in shear, compared to ~1,200 lbf for a solid 2024-T4 rivet of the same diameter.

In Practice:

- Always consult the rivet manufacturer’s datasheet for exact “ultimate” and “working” loads.

- Use a suitable safety factor (often 2–4×) on the working load for structural applications.

- For critical joints, consider proof‐load or pull‐off testing of a sample rivet installation.

By understanding material limits, geometry, and installation quality, you can select rivets that comfortably exceed the loads your assembly will see.