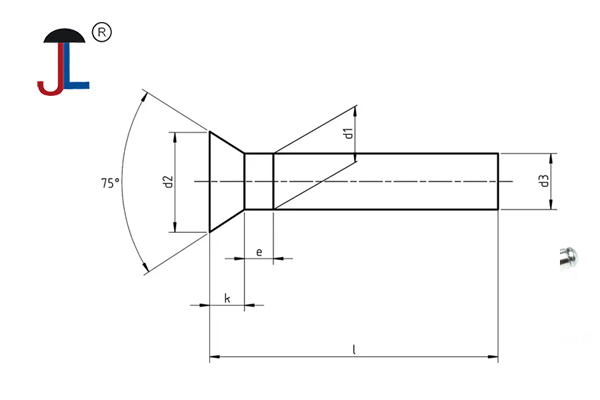

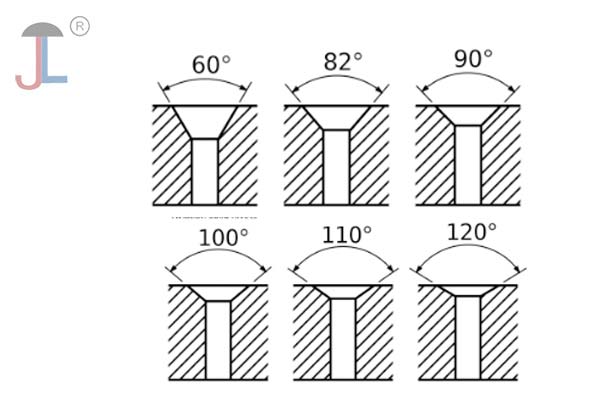

A countersunk rivet is a type of fastener designed so that its head sits flush with or slightly below the surface of the material after installation. Unlike round-head or pan-head rivets, the countersunk rivet has a conical head—typically 90°, 100°, or 120°—that fits into a matching countersunk hole. This creates a smooth and flat surface, ideal for applications where aerodynamics, aesthetics, or clearance are critical.

How Countersunk Rivets Work

Before installing a countersunk rivet, a countersink (a cone-shaped recess) is machined into the material. When the rivet is inserted and deformed during installation, its head fills the recess completely, forming a tight, permanent joint. The result is a clean, flush finish without protruding heads.

Countersunk rivets can be solid, semi-tubular, or blind (pop) types. Blind countersunk rivets are especially useful when access is available from only one side of the workpiece.

Applications

Countersunk rivets are widely used in industries that demand both strength and smooth surfaces:

- Aerospace – Aircraft fuselages, wings, and exterior panels use flush rivets to reduce aerodynamic drag and prevent turbulence.

- Automotive – Car body panels, trims, and frames rely on countersunk rivets for seamless designs.

- Shipbuilding and Marine – To minimize fluid resistance and corrosion risk.

- Mechanical and Electronic Assemblies – For enclosures or devices requiring a clean, snag-free finish.

- Architecture and Furniture – When visible fasteners must blend aesthetically with the surface.

Advantages of Countersunk Rivets

- Flush Surface Finish – The main advantage is a completely flat and clean surface after installation, improving appearance and reducing drag.

- Reduced Risk of Snagging – No protruding heads to catch on moving parts, clothing, or wiring.

- Improved Aerodynamics – Essential for aircraft, vehicles, and other designs where airflow efficiency matters.

- Strong and Reliable Joint – Properly installed countersunk rivets provide excellent shear strength and vibration resistance.

- Versatile and Aesthetic – Suitable for both structural and decorative uses.

Installation Process

Installing countersunk rivets requires precision and the correct tools:

- Drill the Rivet Hole – Slightly larger than the rivet’s shank diameter.

- Create the Countersink – Machine a cone-shaped recess using a countersink cutter with the same angle as the rivet head.

- Insert the Rivet – Place the rivet into the hole so the head fits perfectly into the countersink.

- Set the Rivet – Use a rivet gun (for solid rivets) or a hand/pop riveter (for blind rivets) to deform the tail end, clamping the materials together.

- Inspect the Joint – The head should be flush with the surface, and the tail should be properly formed without gaps.

Professional standards such as MIL-R-47196A specify tolerances for flushness: the head may be up to 0.010 inch above or 0.005 inch below the surface.

Countersunk Rivet Size Chart

| Nominal Diameter (mm) | Head Angle (°) | Head Diameter (mm) | Head Height (mm) | Grip Range (mm) | Typical Application |

|---|---|---|---|---|---|

| 2.4 (3/32") | 100° | 4.5 | 1.2 | 0.5–1.5 | Light electronics, thin sheet metal |

| 3.2 (1/8") | 100° | 6.0 | 1.6 | 0.5–3.0 | Small machinery, furniture |

| 4.0 (5/32") | 100° / 120° | 7.5 | 2.0 | 1.0–4.0 | Automotive panels, mechanical joints |

| 4.8 (3/16") | 120° | 9.0 | 2.3 | 2.0–5.0 | Aerospace and shipbuilding |

| 6.4 (1/4") | 120° | 11.5 | 2.8 | 3.0–6.0 | Structural and high-load connections |

| 8.0 (5/16") | 120° | 14.0 | 3.5 | 4.0–8.0 | Heavy machinery, steel structures |

Note: Dimensions can vary slightly depending on standards (ISO 15984, DIN 661, NAS 1097, or MIL-R-47196). Always confirm angle and grip length compatibility before installation.

Design & Quality Considerations

When using countersunk rivets, engineers must ensure:

- Proper alignment and hole quality (no chatter or eccentricity).

- Correct grip length selection for material thickness.

- Material compatibility to avoid galvanic corrosion (e.g., aluminum rivet in aluminum panel).

- Surface finishing after riveting if required (e.g., shaving or polishing the rivet head).

If the countersink depth or angle is incorrect, the rivet head may sit proud or too deep, reducing joint strength and aesthetic quality.

Conclusion

A countersunk rivet offers the perfect balance between strength, precision, and visual appeal. It’s the preferred fastening method in aircraft, automotive, and mechanical assemblies where flush surfaces are essential. Though installation demands careful preparation and accuracy, the result is a durable, aerodynamic, and professional-looking joint that stands the test of time.