Here’s how solid rivets work, step-by-step:

🔧 1. Components Involved

- Rivet : A short metal cylinder with a head on one end (called the factory head or shop head ) and a smooth, unformed tail on the other.

- Workpieces : The materials (e.g., metal plates, sheets) to be joined.

- Rivet Tooling : Includes a bucking bar and/or a rivet gun/hammer.

🛠️ 2. Installation Process

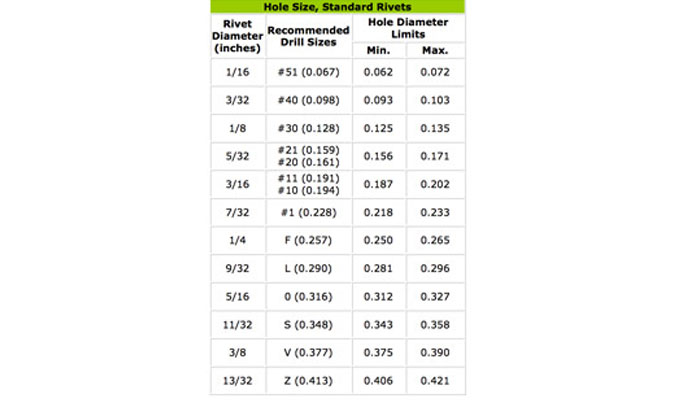

a. Drilling a Hole

- A hole is drilled through the materials being joined. The hole must match the diameter of the rivet closely.

b. Inserting the Rivet

- The solid rivet is inserted into the hole. The factory head remains on one side, and the tail extends out on the opposite side.

c. Setting the Rivet

This is where the actual fastening happens:- One side of the rivet (the head side) is held in place using a dolly or backing tool .

- On the opposite side (tail), a bucking bar or pneumatic rivet gun applies force to deform the tail.

- As the tail is hammered or pressed:

- The metal flows radially outward, forming a second head (called the shop head or buck-tail ).

- This creates a secure, clamped connection between the materials.

d. Final Joint

- Once deformed, the rivet holds the components together permanently .

- The joint relies on shear strength (resisting forces that try to slide the materials past each other) and clamping force (from the tension caused during setting).

✅ Key Advantages of Solid Rivets

- High strength and reliability

- Vibration-resistant

- No risk of loosening over time

- Used in critical applications , like aircraft structures, bridges, and heavy machinery

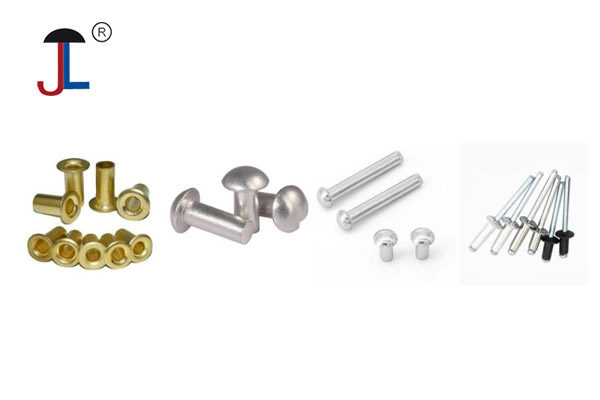

⚙️ Common Materials for Solid Rivets

- Steel,Stainless Steel Rivets

- Aluminum Rivet

- Copper Rivet

- Monel (nickel-copper alloy)

- Titanium (in aerospace)

Summary:Solid rivets work by permanently deforming a metal pin inserted into a hole, creating a secure mechanical joint. Unlike threaded fasteners, they do not rely on threads but on plastic deformation to lock components together.