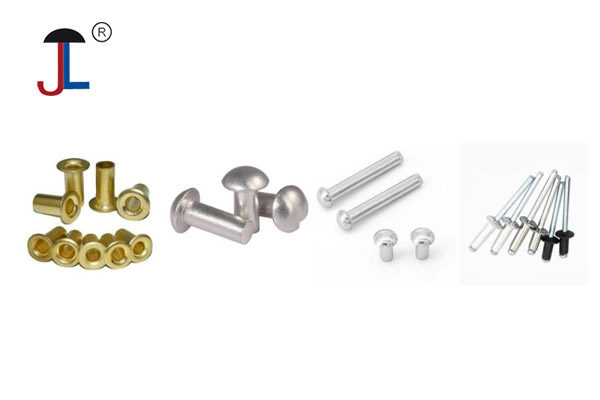

Common rivet types:

Blind Rivets Also known as "pop" rivets, these are useful when you can only access one side of what you are fastening. They are often used in electronics, aerospace, and shipbuilding.There are various sub-types of blind rivets:

- Open-End Rivets: The most common and least expensive blind rivet.

- Closed-End Rivets (Sealed Rivets): Have a cup-shaped end to prevent water ingress.

- Multi-Grip Rivets: Designed for a wider range of material thicknesses.

- Tri-Fold/Peel Rivets: The rivet body splits into petals to create a larger bearing surface, ideal for softer or brittle materials like plastic or fiberglass.

- Structural Rivets: High-strength blind rivets designed for demanding applications.

Flush Rivets Best for use on external surfaces where you want a clean appearance and minimal aerodynamic drag. They have countersunk heads and holes, making them suitable for metal surfaces needing minimal visibility.

Friction-Lock Rivets These are multi-piece rivets that include a stem and sleeve. They are often used in the automotive and aircraft industries.

Self-Piercing Rivets These rivets can pierce materials as they are applied.

Solid Rivets One of the oldest and strongest rivet types, they consist of a solid shaft and head, and are very resistant to tampering and vibration. They are commonly used in aircraft construction and other applications where safety and reliability are critical.

Split Rivets Also known as bifurcated rivets, these are best for softer materials like leather, plastic, and wood. They feature split or sawed bodies, and have sharp tips that allow them to pierce the material.

Tubular Rivets These are similar to solid rivets but have a hole at the end opposite the head, requiring less force to apply. Semi-tubular rivets have shallower holes and may seem like solid rivets when forming the field head. Full tubular rivets have deeper holes and are weaker than semi-tubular ones, but can pierce soft materials more easily.

Rivets can also be classified by the material they are made from, which impacts their properties and applications:

- Aluminum Rivets: Lightweight, corrosion-resistant, and commonly used in aerospace and general applications.

- Steel Rivets: Strong and durable, often used in heavy construction like bridges and building frames.

- Stainless Steel Rivets: Offer excellent corrosion resistance and strength, suitable for locomotive, aircraft, and power-producing industries.

- Copper Rivets: Excellent thermal and electrical conductivity, flexible, often used in electrical appliances.

- Brass Rivets: Corrosion-resistant, non-sparking, and good for applications where both strength and aesthetics are important.

- Titanium Rivets: Used for very heavy applications due to their high strength.