To install solid rivets, there are two main ways you can do it:

-

Installing solid rivets with a hammer

-

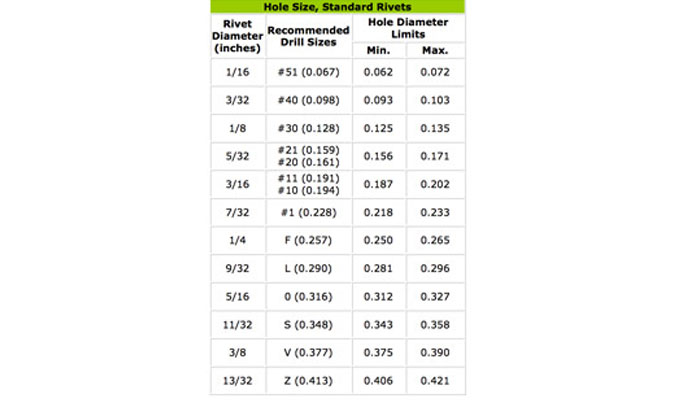

First, drill a hole through the materials to be joined that fits the rivet size exactly.

-

Insert the solid rivet into the hole so that the rivet head rests flush on one side.

-

Use a bucking bar (a flat heavy metal bar) on the opposite side of the rivet.

-

While one person holds the bucking bar against the rivet tail, another person strikes the rivet head with a hammer.

-

Hammer the rivet until the tail on the back side deforms and flattens, forming a second head that securely clamps the materials together.

This method requires access to both sides of the material and is often done by two people—one holding the bucking bar and one hammering. The rivet shank forms a strong bond when properly peened with the hammer and bucking bar, creating a permanent joint.

-

-

Installing solid rivets without a rivet gun

-

If you do not have a rivet gun, you can still install solid rivets manually using household tools such as a hammer, pliers (or vice grip), and a drill.

-

Drill a hole slightly larger than the rivet shank diameter through the joined materials.

-

Insert the rivet into the hole.

-

Hold the rivet head firmly with pliers or a vice grip to prevent it from spinning.

-

Use a hammer to strike the protruding end of the rivet shank, hammering it evenly to deform and flare the tail end, securing the joint.

-

You may use two hammers: one steadies the rivet head, while the other hammers the tail to spread it out.

-

Check that the joint is tight and the rivet firmly holds the materials together.

This approach requires care and force, as manual hammering without a rivet gun needs precision to avoid damaging materials or injuring yourself.

-

Both methods depend on having access to both sides of the workpiece and rely on deforming the solid rivet’s tail to clamp the materials permanently. The main difference is that the hammer and bucking bar method is more traditional and efficient, while the no-rivet-gun methods use improvised tools like pliers and multiple hammers to replace specialized rivet guns. Safety precautions such as eye protection and steady hand positioning are important to avoid injury.